AIR CHECK

I WORK ENGINEERING L.P.

SCIENCE MADE EASY:

We provide compressed air & gas testing services to industry. Our customers are manufacturers where the use of compressed air is critical such as Food & Beverage and many others.

AirCheck✓™ team of experts collect samples from your system that are sent to our laboratory for analysis. We then caccurately determine the purity of your compressed air/gas and provide you with a report that is internationally accepted and recognized.

Here's what you can expect:

- End to end support from qualified staff

- Quick turn around for audits

- Accurate results

- Help meeting ISO standards

WHY IT'S IMPORTANT:

Compressed Air that is contaminated or does not meet required purity standards can affect product quality. damage machinery or endanger health and safety. It is important to check compressed air quality.

Some industries have regulations or guidelines that include requirements for compressed air purity. In addition, audit and certification may be required

Prevent product contamination

- Rusty Particles

- Excess Water

- Oily Piping

- Mold and Bacteria

Monitor the health of your system

- Compressor Fittings

- Disribution Piping

- Storage Receivers

Meet certification requirements

- SQF - Safe Quality Food

- FDA - Food and Drug Administration

- BRC - British Retail Consortium

- PrimusGFS - GFSI Scheme

Meet equipment requirements

- Class 0 Oil

- Clean Dry Air

- Praticle Free

ISO

ISO (International Standards Organization) is the world's largest developer and publisher of international standards. There are three standards currently in use which directly relate to compressed air quality (purity) and testing.

These are : ISO 8573 Series / ISO 12500 Series / ISO 7183

The most commonly used standard is the ISO 8573 Series and in particular ISO 8573-1:2010

Which of the three standards should I use ?

OBJECTIVE

- To specify the purity of compressed air required at a particular point in a compressed air system. ---> ISO 8573-1:2010

- To test a compressed air system for one or more specific contaminants. ---> ISO 8573 Part 2 to 9

- To verify the performance of compressed air purification equipment. ---> FILTERS-ISO 12500 / DRYER-ISO 7183

- To Benchmark the performance of compressed air purification equipment. ---> FILTERS-ISO 12500 / DRYER-ISO 7183

STANDARD TO USE

- ISO 8573-1:2010

- ISO 8573 PARTS 2 TO 9

- FILTERS-ISO 12500 SERIES / DRYERS-ISO 7183

- FILTERS-ISO 12500 SERIES / DRYERS-ISO 7183

WHO WE SERVE:

Dietary Supplements

Food Manufacturing

Food Packaging

Manufacturing

Medical Devices

Pet Food

Pharmaceutical

Power Stations

OUR LAB:

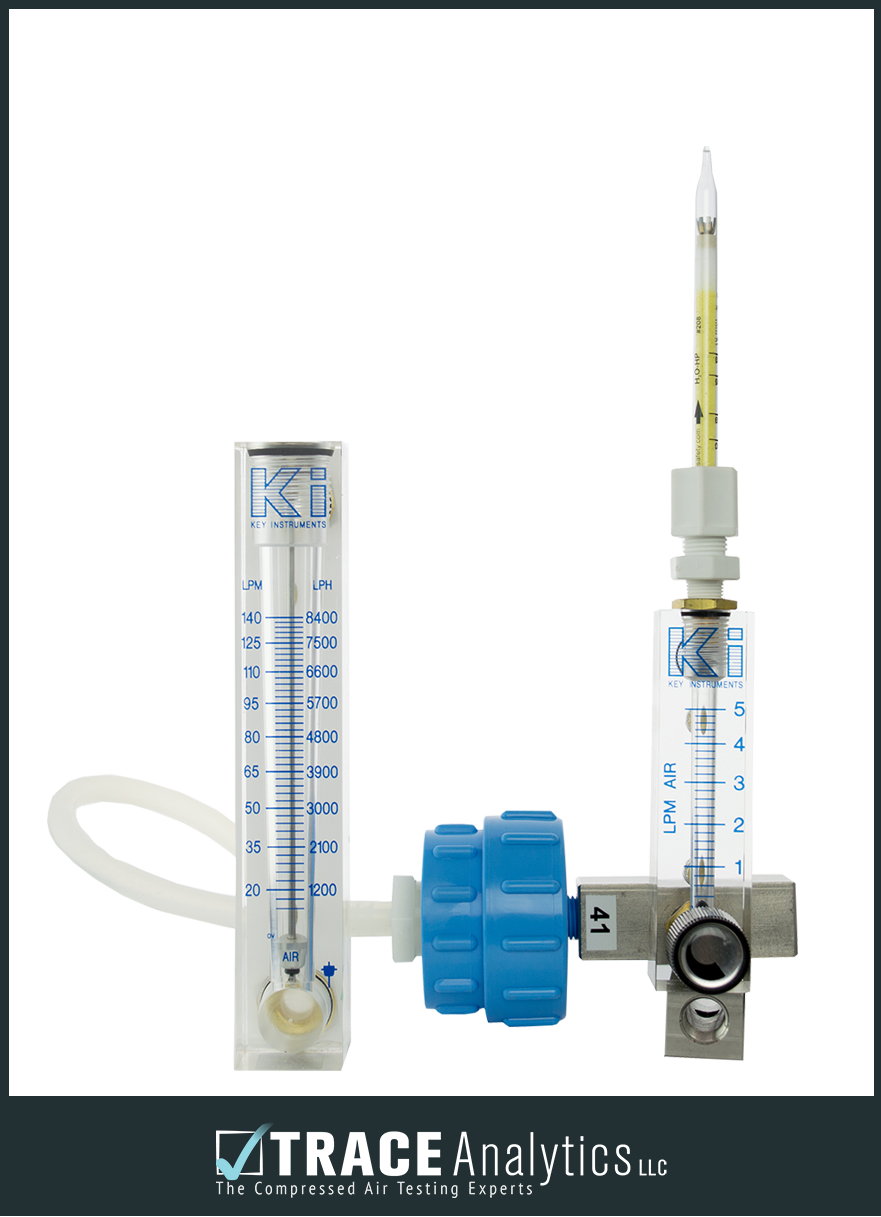

Our laboratory partner is Trace Analytics, a pioneer in compressed air testing. Established since 1989 and dedicated only to compressed air and gas testing, we use innovative testing methods that are easy-to-use and highly accurate.

- A2LA accredited – #0322-01

- ISO 17025 certified

- HACCP certified

- International Laboratory Accreditation Cooperation (ILAC)

- International Recognition

- Member of:

- National Fire Protection Association

- International Society of Pharmaceutical Engineers

- Medical Gas Professional Healthcare Organization

For more information, please visit www.airchecklab.com

TEST & PACKAGES

We work mainly using ISO 8573.1 as the specification for evaluating compressed air purity. However, other specifications are available.Here's what you can expect:

- Risk assessment of your system

- Sample collection by certified experts

- A2LA accredited lab

- ISO 17025 accredited report

- Meet various industry-specific guidelines

- Accurate results

- Documentation to meet certification requirements

Specifications we work with:

- ISO 8573.1

- NFPA 1989

- NFPA 99

- OSHA

- OGA

- CSA

- BCAS (Food Grade Air)

- More

WHAT WE TEST:

PARTICLES

Rust, dirt, and metal shavings are just a few examples of possible particle contamination.

WATER

Length and condition of distribution piping, drops, dead-ends, condensate drain traps, and the use of polymer tubing can contribute to excess moisture.

OIL

Even oil-free compressors can be contaminated with oil vapor(gaseous hydrocarbons) from intake air.

MICROORGANISMS

An improperly maintained compressor can provide conditions (water + oil + warm temperature) needed for microbial growth.

CERTIFICATION

Certifications/Industry Regulations - Compliance:

There are industries where certifications will need to be obtained. To obtain certification, audits are carried out by independent inspection and certification companies such as SGS, Intertek, NSF and TUV NORD. We will help your pass your next audit.Food:

- British Retail Consortium (ฺBRC)

- British Compressed Air Society (ฺBCAS) (Food Grade Air)

- Safe Quality Food Institute (SQF)

- Food Safety System Certification (FSSC)

- Federal Drug Administration (FDA)

- Dietary Supplement and Education Act of 1994 (DSEA)

- Global Food Safety Initiative (GFSI)

- Canadian Food Safety Enhancement Program (FSEP)

Others:

- ANSI

- ISA

- HALAL

- ISO

- Federal Food, Drug and Cosmetic Act(FEDCA)

- International Society of Pharmaceutical Engineers’(ISPE)

OTHER SERVICES

Other than serving the manufacturing industry, we also provide air and gas testing for the following:Breathing Air

- Commercial & Sport Dive

- Fire Fighting

- Industrial Breathing Air

- Welding

- Sandblasting

- Spray Painting

- Tank Cleaning

Others

- Medical Air & Gas ISO 8573-1:2010

- Microbial Testing ISO 8573-7 :2003

- Pure Gas Testing ISO-8573-6:2003

AIR TESTING VIDEOS

Need SQF Air Purity, Food Grade Air Testing, Microbial Air Testing, Food Grade Nitrogen Testing, BRC Monitoring, BCAS, ISO 8573-1, ISO 8573-7 , or Custom Specification Air Testing? Contact the AirCheck✓™ Team of Experts for your Food Grade Air and SQF Air Testing needs.